The exceptional mixture of properties delivered by aluminum and its alloys mark aluminum as one of the most adaptable, cost-effective, and attractive engineering materials for a far-reaching uses from wrapping foil to the aerospace applications. It is not the surprise Aluminum alloys are just next to steels in use as structural metals.

So if anybody ask you what good is Aluminum, you just rap the below properties.

- Non-magnetic

- Reflective

- Non-sparking

- Ductile at low temperatures

- Corrosion resistant

- Non-combustible

- Light

- Sturdy

- High strength-to-weight ratio

- Resilient

- Non-toxic

- Heat conducting

- Electrically conducting

How to understand the Aluminum Alloy Designation System ?

Before you go into designation you should understand its key classification. Aluminum alloys are primarily classified as cast alloys and wrought alloys. Cast Al alloys are melted into the molds in liquid form and prepared to solidify into the required shape. On further it’ll be machined but definitely not subjected to operations like forging, rolling etc.

Wrought aluminum alloys are responsive for all the metal working processes like forging, rolling, extrusion, deep drawing etc.

The wrought and cast aluminums follows quite a different identification procedure. The wrought will have a 4-digit identification system whereas the castings will have a 3-digit and 1-decimal place system to indicate its form

Wrought Aluminum Alloy Identification System.

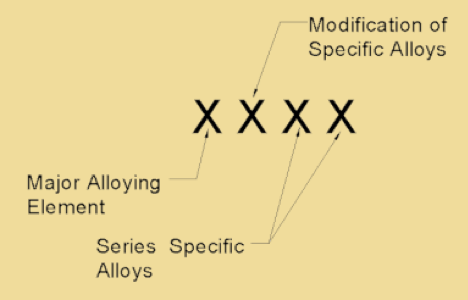

The first digit indicates the major alloying element, which has been added to the aluminum alloy and is often used to describe the aluminum alloy series, i.e., 1000 series, 2000 series, 3000 series, up to 8000 series

The second single digit indicates a modification of the specific alloy, and the third and fourth digits are denotion given to identify a specific alloy in the series. Example: In alloy 2524, the number 2 indicates that it is of the copper alloy series, the 5 indicates that it is the 1st modification to the alloy 2024, and the 24 identifies it in the 2xxx series.

The 1xxx series aluminum alloys (pure aluminums) is exempted from above identification system. For 1xxx series, the last 2 digits provide the minimum aluminum percentage above 99%, i.e., Alloy 1316 (99.16% minimum aluminum).

| Wrought Aluminum Alloy Series | Major Alloying Element |

| 1000 series | 99.000% minimum Aluminum |

| 2000 series | Copper |

| 3000 series | manganese |

| 4000 series | silicon |

| 5000 series | magnesium |

| 6000 series | Magnesium and silicon. |

| 7000 series | zinc |

| 8000 series | Other Elements |

Cast Aluminum Alloy Identification System.

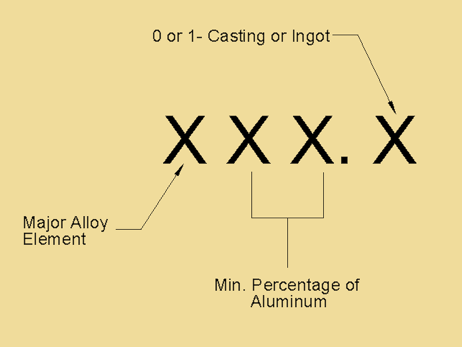

According Aluminum Association, Cast Al, and the first digits reveals the major alloying element, the next two digit denotes Min percentage of Aluminum. Last digit denotes casting and ingot represented by 0 or 1 respectively.

| Cast Aluminum Alloy Series | Major Alloying Element |

| 100.0 series | 99.000% minimum Aluminum |

| 200.0 series | Copper |

| 300.0 series | manganese |

| 400.0 series | silicon |

| 500.0 series | magnesium |

| 600.0 series | Magnesium and silicon. |

| 700.0 series | zinc |

| 800.0 series | Other Elements |

| 900.0 | Unused Series |

Temper Designation System

Now that we understood two type of indemnification system for Aluminum alloys, we will get into distinctly different type of Aluminum within those series. Heat Treatable Aluminum alloys and the Non-Heat Treatable Aluminum alloys are the two further classification.

Within wrought alloy, they can be classified like shown below

| Wrought Aluminum Alloy | Type |

| 1xxx, 3xxx, and 5xxx series | Non-Heat treatable |

| 2xxx, 6xxx, and 7xxx series | Heat Treatable Aluminum alloys |

| 4xxx | This consist of both type of Alloys |

In Cast Al alloys, 2xx.x, 3xx.x, 4xx.x and 7xx.x series are heat treatable.

How they do Heat Treatment?

We can alter the mechanical properties of the heat treatable alloys through a process of thermal treatment. Heat Treatment is the process of heating the alloy to an elevated temperature of 990 and followed by quenching, usually in water, to produce a supersaturated solution at room temperature.

It is then usually followed by aging. Aging is the precipitation of a portion of the elements or compounds from a supersaturated solution in order to yield desirable properties.

The non-heat treatable alloys mechanical properties can be improved through Strain Hardening. Strain hardening is the method of increasing strength through the application of cold working.

The Temper Designation System by the extension of the alloy numbering system and consists of a series of letters and numbers which follow the alloy designation number and are connected by a hyphen. Examples: 6061-T6.

| Designation Letter | What it means? |

| XXXX.FX | As fabricated |

| XXXX.OX | Annealed |

| XXXX.HX | Strain Hardened H1 – Strain Hardened Only H2 – Strain Hardened and Partially Annealed. H3 – Strain Hardened and Stabilized. H4 – Strain Hardened and Lacquered or Painted. HX2 – Quarter Hard HX4 – Half Hard HX6 – Three-Quarters Hard HX8 – Full Hard HX9 – Extra Hard |

| XXXX.WX | Solution Heat Treated |

| XXXX.TX | Thermally Treated T1 – Naturally aged after cooling from an elevated temperature shaping process, such as extruding. T2 – Cold worked after cooling from an elevated temperature shaping process and then naturally aged. T3 – Solution heat treated, cold worked and naturally aged. T4 – Solution heat treated and naturally aged. T5 – Artificially aged after cooling from an elevated temperature shaping process. T6 – Solution heat treated and artificially aged. T7 – Solution heat treated and stabilized (overaged). T8 – Solution heat treated, cold worked and artificially aged. T9 – Solution heat treated, artificially aged and cold worked. T10 – Cold worked after cooling from an elevated temperature shaping process and then artificially aged. TX51 or TXX51 – Stress relieved by stretching. TX52 or TXX52 – Stress relieved by compressing. |

Substituting light metals for heavy metals as general design solution in aerospace structure is now reached to various industries like cars, highway structures, buildings etc. This substitution from heavy metals can be difficult for those who have little experience with aluminum alloys. I hope this post will be helpful for them to get introduction about Aluminum alloys.

Happy Learnings!

Discussion about this post